1, composition

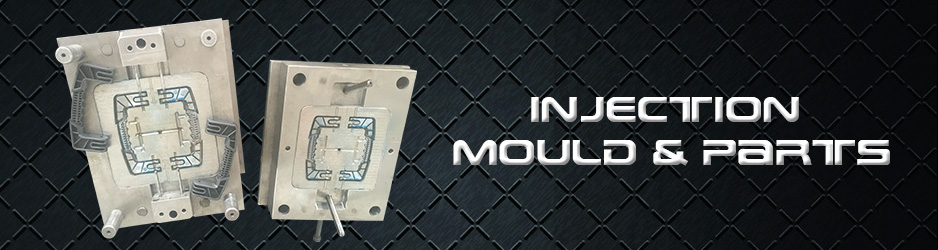

Blow molding mold, casting mold and hot forming die structure is relatively simple.

Mold, injection mold and the mold structure is relatively complex, make this kind of mold parts more.

Basic parts:

(1) forming parts, including die, punch, various forming core, is forming products inside and outside surface or the upper and lower end face, side hole, lateral concave and threaded parts.

(2) supporting fixed parts, including mold base plate, a fixed plate, plate, block, etc., to the fixed mould or bearing pressure.

(3) guide parts, including the guide pillar and guide bush, for determining the relative position of mould or launch mechanism motion.

(4) core pulling parts, including pin, slider, etc., in the mold core is open to take activities, make the product mold release.

5 parts, including the push rod, push, push, push board, pushing a ring, push rod fixed plate and push plate, etc, to make products mold release.More promotion of injection moulds with a standard mould frame, the die set is composed of structure, form and size have standardization and serialization of the basic parts of complete, the cavity can be processed according to the shape of the products themselves.With a standard formwork is helpful to shorten the molding cycle.

2, the common mold base parts

Mold base plate (panel) : fix the front mould injection molding machine.

Runner plate (nozzle plate) : open mould when removing waste, handle, make it off automatically (three board module).

Set fixed mould board (A board) : part molding products before.

Dynamic model of fixed plate (B) : part molding products.

Block: die, its role is to make the roof there is enough space.

Push board: open mode through the plunger, the top piece, inclined top parts will launch soon launched from the mold.

After the moving mould plate (floor) : the fixed mold in injection molding machine.

Plays a role of guide positioning guide pillar and guide bush:, auxiliary before and after mold opening mold, and mold and basic position.

Columns (hold) : increasing the intensity of B plate, plate deformation effectively avoid long-term production lead to B.

Roof guide pin (the company) : guide positioning push board, ensure smooth out.

Get Quote

Injection Mold structural parts

2017 10/16

Previous: Plastic Injection Molds

Next: injection molding