With the rapid development of plastic industry and general engineering plastics in such aspects as strength unceasing enhancement, the application range of the plastic products are also constantly expanding, the amount of plastic products is also rising.

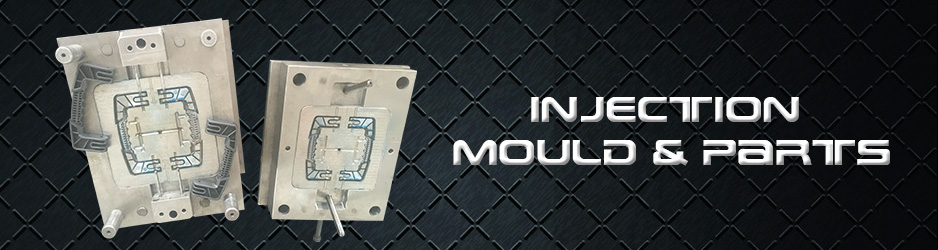

Plastic products of plastic mold is a kind of production tools. It consists of several groups of parts, the combination with molding cavity.Clamped injection, mold in injection molding machine, molten plastic injection molding die cavity, and the cavity cooling stereotypes, then separated from mould, via ejection system will leave mould products out of the cavity roof, the mould closed again for the next injection, the injection molding process is a cycle.

General plastic mold consists of two parts, dynamic model and fixed model, dynamic model is installed on the movement of the injection molding machine templates, set module is installed on the injection moulding machine fixed template.Dynamic model in injection molding and mold closing a gating system and the cavity, cavity when moving die and die separation in order to take out the plastic products.

Structure though because of the plastic varieties and properties of the mould, the shape and structure of the plastic products and the type of injection machine and so on different and might go, but the basic structure is the same.Mold is mainly composed of gating system, air-conditioning system, molding parts and structural parts.The pouring system and is part of the direct contact with plastic molding parts, and with the plastic and products, is the most complicated in the mold, the biggest change, request processing smoothness and accuracy of the highest part.

Gating system refers to the plastic from the nozzle into the mold cavity in front of the flow channel section, including the mainstream way, slag hole, distributary channel and gate, etc.Molding parts refers to the various parts of the product shape, including the moving die, die and cavity, core, molding and vent, etc.

Plastic mould in high technology driven and pillar industry in China under the impetus of the application requirements, formed a huge industry chain, from upstream raw material industry and processing, testing equipment to the downstream machinery, automobiles, motorcycles, home appliances, electronic communication application and so on several big industry, building materials, plastic mold development vitality.